I thought some of you may be interested in seeing some of the work that goes into the making of a tool. I may start a blog of some sort in the future but for now I’ll just post a few pictures now and then from my shop as things progress on the next batch of Infill Planes.

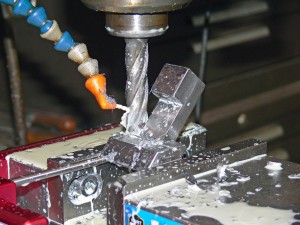

One of the main pieces of a hand plane is called the frog. In my infill plane the frog is machined out of a piece of steel one inch thick. Here I am milling the general contours of the frog. I clamp the work piece in a vise on my Bridgeport mill. I use coolant to lubricate and cool the cutter.

One of the main pieces of a hand plane is called the frog. In my infill plane the frog is machined out of a piece of steel one inch thick. Here I am milling the general contours of the frog. I clamp the work piece in a vise on my Bridgeport mill. I use coolant to lubricate and cool the cutter.

The frog is attached to the sole of the plane with rivets. Here we are drilling the four rivet holes through the base of the frog. Each hole gets a small countersink, or angle cut around the top lip of the hole for the rivet to “swell” into when I pein (sometimes spelled peen) them into the matching holes in the base and frog. This type of joint is surprisingly strong and durable because the rivets expand to fill the holes, leaving no room for “wiggle” while the countersink at each end won’t allow the rivet to come out. The peining is accomplished with a ball pein hammer, a punch and a “dolly”. The dolly is a heavy piece of metal that backs up the opposite end of the rivet as I hammer, much like an anvil.

The frog is attached to the sole of the plane with rivets. Here we are drilling the four rivet holes through the base of the frog. Each hole gets a small countersink, or angle cut around the top lip of the hole for the rivet to “swell” into when I pein (sometimes spelled peen) them into the matching holes in the base and frog. This type of joint is surprisingly strong and durable because the rivets expand to fill the holes, leaving no room for “wiggle” while the countersink at each end won’t allow the rivet to come out. The peining is accomplished with a ball pein hammer, a punch and a “dolly”. The dolly is a heavy piece of metal that backs up the opposite end of the rivet as I hammer, much like an anvil.